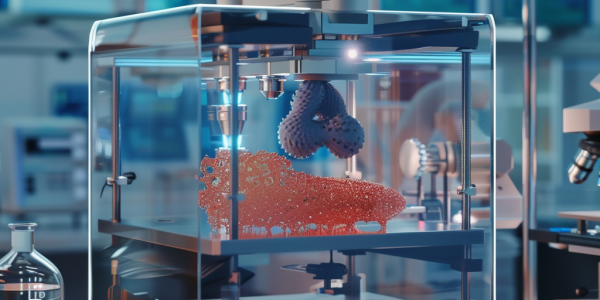

Penn State Researchers Unveil Revolutionary HITS-Bio Bioprinting System

Penn State University researchers have launched the High-throughput Integrated Tissue Fabrication System for Bioprinting (HITS-Bio), a groundbreaking technology that produces functional biological tissues ten times faster than traditional methods. Utilizing cell clusters known as spheroids, HITS-Bio ensures high cell viability while enabling rapid assembly of complex tissue structures. This innovative system promises to revolutionize regenerative medicine, with potential applications in organ transplantation and advanced therapeutic interventions.

MIT Advances 3D-Printed Active Electronics, Paving Way for Semiconductor-Free Manufacturing

MIT researchers have made groundbreaking advancements in 3D-printed active electronics, introducing semiconductor-free logic gates that could revolutionize electronics manufacturing. This innovation aims to democratize technology, allowing individuals and businesses to create their own electronic devices, reducing dependency on traditional semiconductor processes. With the potential to transform various industries, this research paves the way for more accessible and sustainable manufacturing solutions.

YouTuber Creates Rideable Motorcycle from 3D-Printed LEGO Bricks

YouTuber Matt Denton has created a stunning rideable motorcycle made entirely from oversized 3D-printed LEGO bricks, inspired by the classic LEGO Technic 8810 Cafe Racer. This innovative project combines engineering and creativity, showcasing Denton’s skills while capturing the hearts of LEGO and motorcycle enthusiasts alike. With a playful design and functional features, Denton’s LEGO motorbike pushes the boundaries of imagination and technology.

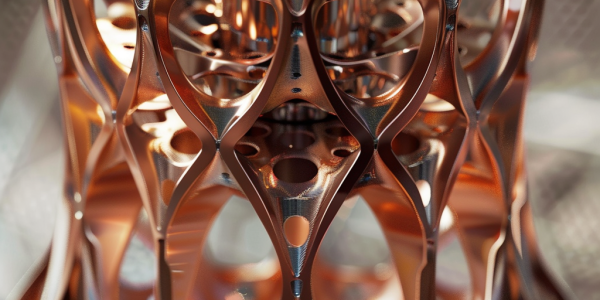

Revolutionary AI-Generated Rocket Engine Designed in Two Weeks

Discover the groundbreaking 20,000 horsepower AI-generated rocket engine designed in just two weeks by Leap 71. This innovative engine, 3D-printed in copper, showcases the future of aerospace engineering with its state-of-the-art design and remarkable performance. Watch the test firing video to witness the cutting-edge technology driving the future of space exploration.

Breakthrough in Soft Robotics with 3D-Printed Mini-Actuators

Researchers at North Carolina State University have achieved a breakthrough in soft robotics with 3D-printed mini-actuators that offer precise control over small robots less than a millimeter thick. By combining multi-material 3D printing and shape memory polymers, the team has created miniature hydraulic actuators that enable intricate movements and shape changes in soft robots. This innovation has vast potential in fields like healthcare and advanced manufacturing, showcasing the power of 3D printing technologies in revolutionizing soft robotics.

First Metal 3D Printing Successfully Completed on International Space Station

Breaking news in the world of science and exploration – the very first metal 3D printing has successfully taken place on the International Space Station. This milestone achievement opens up new possibilities for space technology and in-orbit manufacturing, marking a significant advancement in space exploration.

New Flame-Retardant Photopolymer Developed for Aircraft Cockpit Components

Learn about the latest flame-retardant photopolymer designed for Additive Manufacturing (AM) to meet aerospace standards. Join the free webinar on May 21 featuring experts from the University of Dayton Research Institute and 3D Systems to explore the innovative material for aircraft cockpit components.

Formlabs Introduces Form 4: A Revolutionary 4th Generation Desktop Resin 3D Printer

Formlabs introduces Form 4, a cutting-edge 4th generation desktop resin 3D printer, revolutionizing the 3D printing industry with LED-based LFD technology. This groundbreaking printer offers impeccable surface quality, high throughput, and a comprehensive ecosystem for streamlined post-processing. Form 4 is set to transform various industries, from dentistry to automotive, fostering rapid innovation and transcending traditional manufacturing constraints.

Groundbreaking 3D Printed Pills with Timed Drug Release Developed by University of Nottingham Researchers

Researchers from the University of Nottingham have developed 3D printed pills using Multi-Material InkJet 3D Printing, allowing for personalized medication with timed drug release capabilities. This innovative method controls drug release rate within the tablet, simplifying complex medication regimens into a single dose. The technology has the potential to revolutionize drug delivery and advance personalized medicine, although challenges like the need for additional formulations remain. With the ability to print 56 pills in a single batch, this advancement showcases the potential for mass production of personalized medicines for diseases requiring precise timing and dosage accuracy.

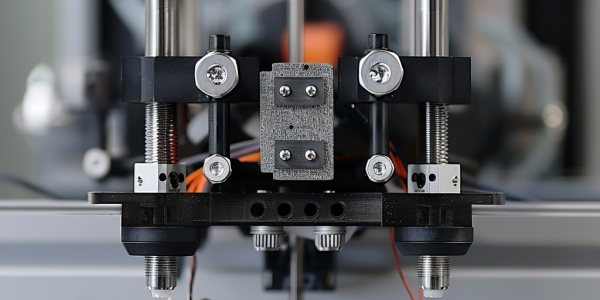

New Autonomous 3D Printer Revolutionizes Parameter Creation for Unknown Materials

A groundbreaking development in 3D printing has emerged as scientists introduce a new FDM 3D printer capable of autonomously creating parameters for unknown materials. This innovation, spearheaded by experts from MIT’s Center for Bits and Atoms, NIST, and Demokritos, aims to revolutionize sustainable 3D printing practices. By developing an extruder that gathers filament data during printing, the team has successfully implemented a mathematical model to determine optimal printing parameters for various materials. This advancement holds the potential to enhance the utilization of unique FDM filaments with superior sustainability compared to conventional polymers.