Study Finds Listeria monocytogenes Bacteria Persist in Ready-to-Eat Food Production Environments

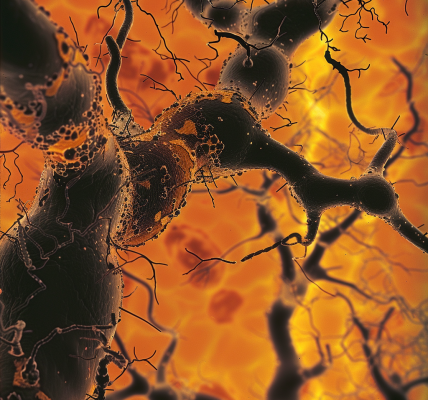

A recent study conducted by scientists from the Quadram Institute and the UK Health Security Agency has revealed that, despite cleaning and sanitation, Listeria monocytogenes bacteria are able to persist in ready-to-eat (RTE) food production environments. The study is part of ongoing research to better understand what causes L. monocytogenes to persist in RTE food settings following a fatal UK foodborne illness outbreak in 2019 linked to RTE hospital food contaminated by the pathogen.

Led by María Díaz, Ph.D., M.Sc., the scientists conducted their research at a RTE food factory with a history of recurrent L. monocytogenes detection in certain non-food-contact areas of the facility. Over a ten-week period, the team sampled the floor of the factory’s preparation area, where ingredients were kept at 4 °C, and a production area where food packaging and assembly took place, and the food was kept at 10 °C. Sampling was conducted both before and after cleaning. The scientists cultured the samples and subjected isolates to genetic sequencing.

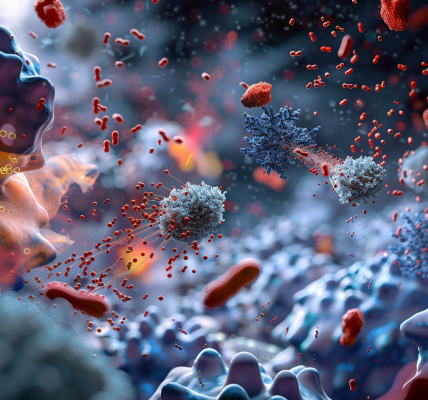

The researchers found the populations of bacteria that coexist with L. monocytogenes to be stable over time, having adapted to conditions on the factory floor, including the food safety controls implemented at the facility. Since L. monocytogenes are supported by a stable community of other bacteria, Dr. Díaz believes that, to fully eliminate the pathogen from a facility, it may be necessary to develop new strategies to alter entire bacterial populations.

Although bacterial populations and proportions may be stable regardless of cleaning, Dr. Díaz explained that cleaning is still crucial, as it still reduces bacterial load and helps mitigate cross-contamination.

The scientists also noted a significant difference among bacterial populations in areas of the facility that were kept at different temperatures, despite the regular movement of staff from one area to another. This may suggest that bacterial populations are highly adapted to the different environments, and that the bacteria present in a facility are established populations rather than bacteria introduced from the outside world.

Dr. Díaz hopes that her findings will improve the understanding of microbial communities and L. monocytogenes survival in different environments throughout RTE facilities, which could help inform more accurate validation of cleaning methods, as well as laboratory models to investigate new methods for inactivating the pathogen. Dr. Díaz will officially present her data at the 2024 Microbiology Society Ann