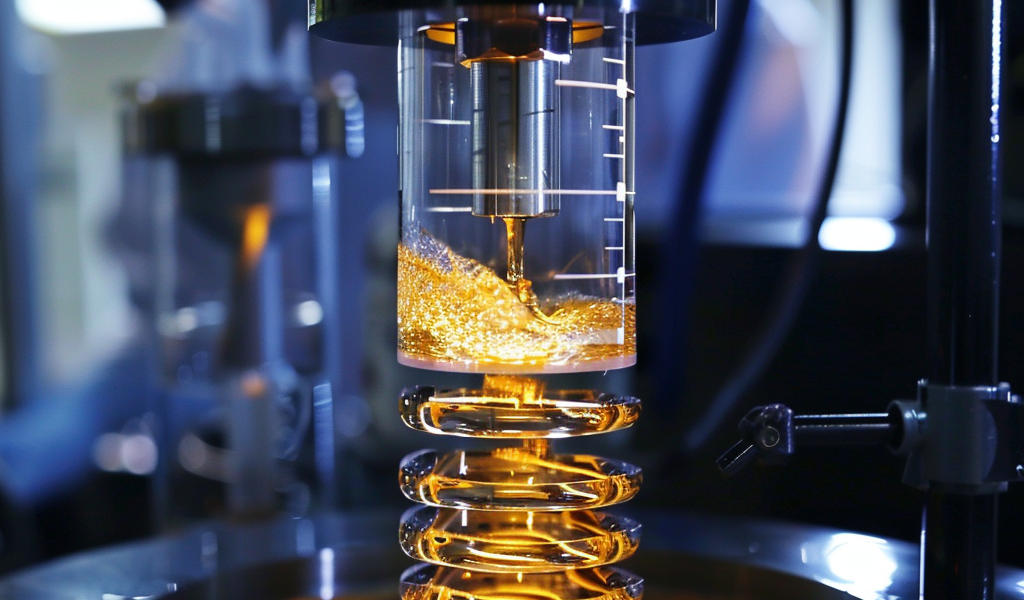

In a groundbreaking discovery, researchers at Flinders University in South Australia have successfully created various types of gold nanotechnology particles by manipulating water flow in a revolutionary vortex fluidic device, all without the use of harmful chemicals. This innovative approach in the green chemistry lab at the Flinders Institute for Nanoscale Science and Technology not only led to the production of gold nanoparticles but also unveiled a contact electrification reaction in water within the device, resulting in the generation of hydrogen and hydrogen peroxide.

Collaborating with scientists from Australia and overseas, the team explored the size and shape variations of gold nanoparticles through different vortex fluidic device processing parameters and concentrations of gold chloride solution. This research, detailed in a recent publication in Small Science, sheds light on the potential applications of this new method in various chemical and biological reactions.

PhD candidate Badriah Alotaibi, who spearheaded the study, expressed the significance of their findings, stating, “Through this research, we have discovered a new phenomenon in the VFD – the photo-contact electrification process at the solid-liquid interface, which holds promise for future applications in diverse fields. Additionally, we have successfully synthesized pure gold nanoparticles in water within the VFD, eliminating the need for commonly used chemicals and reducing waste production.”

The method developed by the researchers is not only environmentally friendly but also efficient, scalable, and yields nanoparticles with unique properties. The size and shape of gold nanoparticles play a crucial role in various applications such as drug delivery, catalysis, sensing, and electronics, owing to their distinct physical, chemical, and optical characteristics.

The vortex fluidic device, conceptualized by Flinders University Professor Colin Raston a decade ago, features a rapidly rotating tube with liquids delivered through jet feeds. By adjusting rotational speeds and utilizing external light sources, researchers can tailor the synthesis of particles according to specific requirements.

Professor Raston emphasized the global significance of this technology, stating, “Researchers worldwide are increasingly recognizing the value of the continuous flow, thin film fluidic device for sustainable nano-scale processing methods. In our latest experiment, we propose that the high shear forces generated within the VFD play a crucial role in the successful creation of gold nanoparticles with precise characteristics.”