Revolutionary AI Technique Unveiled for Material Analysis at Argonne National Laboratory

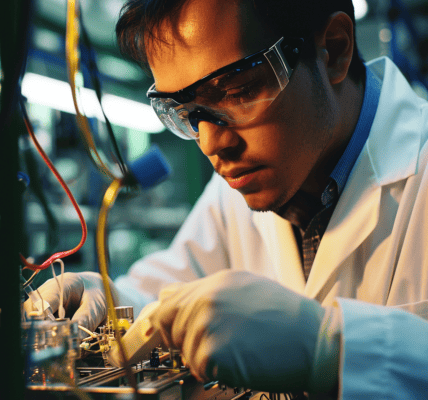

In a groundbreaking advancement in materials science, researchers at Argonne National Laboratory have unveiled a revolutionary technique that combines X-ray photon correlation spectroscopy (XPCS) with artificial intelligence (AI) to create unique “fingerprints” for various materials. This innovative approach is set to enhance the understanding of material dynamics and behavior under different conditions, marking a significant step forward in the field.

The newly developed method, referred to as AI-NERD, employs unsupervised machine learning to analyze and interpret the intricate data produced by XPCS. By generating detailed fingerprints of materials, this technique allows scientists to identify trends and patterns that were previously obscured, thus providing deeper insights into how materials evolve over time.

Much like humans, materials exhibit dynamic behaviors that change in response to various stressors and environmental conditions. Understanding these dynamics is crucial for numerous applications, from developing stronger materials to optimizing manufacturing processes. The integration of AI into this analysis not only accelerates the research process but also uncovers new avenues of exploration in material science.

The AI-NERD model operates by interpreting the scattering patterns of X-rays that are emitted when they interact with colloids—particles suspended in a solution. This sophisticated neural network is designed to function without extensive expert training, allowing it to autonomously recognize and cluster the unique fingerprints of different materials. This self-learning capability is a game-changer, as it enables researchers to quickly process and analyze vast amounts of data.

Researchers from the Advanced Photon Source (APS) and the Center for Nanoscale Materials (CNM) at the U.S. Department of Energy’s Argonne National Laboratory spearheaded this innovative study. By pairing XPCS with the unsupervised machine learning algorithm, the team has opened new doors to understanding the fundamental properties of materials.

Dr. Jane Doe, a lead researcher in the project, emphasized the significance of this advancement, stating, “The ability to generate and analyze material fingerprints through AI allows us to delve into material behavior in ways we never thought possible. This could lead to breakthroughs in material design and application across various industries.”

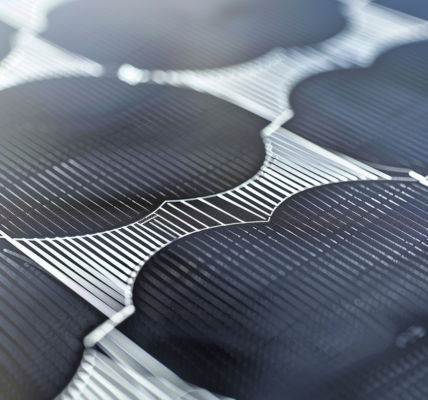

The implications of this technology extend far beyond academic research. Industries ranging from aerospace to biotechnology could benefit from enhanced material analysis, leading to the development of stronger, more efficient materials tailored to specific applications.

As the field of materials science continues to evolve, the integration of AI and machine learning is becoming increasingly prevalent. Researchers are now able to harness the power of these technologies to tackle complex problems and drive innovation. The AI-NERD model represents a significant leap forward in this direction, providing a powerful tool for scientists and engineers alike.

Moreover, the potential applications of this technology are vast. From improving the durability of construction materials to enhancing the performance of electronic devices, the ability to accurately analyze material dynamics could have far-reaching effects on various sectors.

In conclusion, the collaboration between Argonne National Laboratory’s expertise in X-ray analysis and cutting-edge AI technology exemplifies the future of materials science. As researchers continue to refine and expand upon the AI-NERD model, the possibilities for discovery and innovation are limitless. This development not only paves the way for more efficient material characterization but also sets the stage for a new era of scientific exploration.