A revolutionary 20,000 horsepower AI-generated rocket engine has been designed in just two weeks, resembling a creation from a sci-fi artist’s imagination. Leap 71, a Dubai-based AI engineering company, utilized its Large Computational Engineering Model, Noyron, to autonomously create this cutting-edge design without any human intervention.

Traditionally, rocket engine designs require extensive manual engineering by numerous engineers over months or even years using programs like CAD. However, the AI model developed by Leap 71 drastically accelerates this process, generating new engine iterations within minutes.

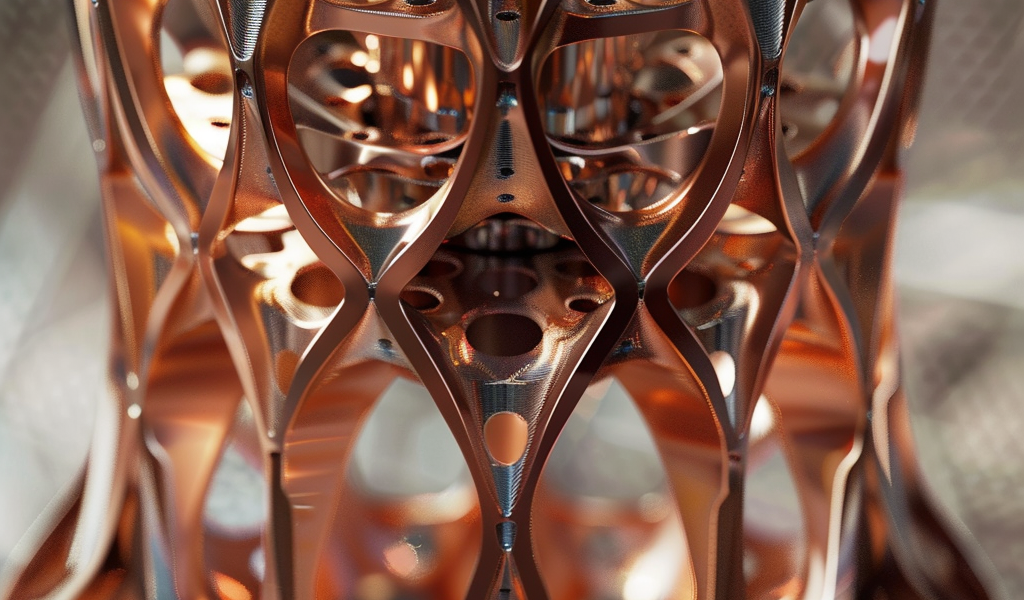

The rocket engine, 3D-printed in copper by German company AMCM and post-processed at the University of Sheffield, features a unique injector head with a state-of-the-art coaxial swirler to effectively mix cryogenic liquid oxygen and kerosene propellants.

This innovative engine, capable of producing 5 kN of thrust (equivalent to 20,000 horsepower), is intended for the final ‘kick stage’ of an orbital rocket. The successful test firing of the engine at Airborne Engineering’s UK facility in Wescott showcased its remarkable performance.

Despite initial skepticism about using copper due to its low melting point, active cooling mechanisms enable the creation of compact, high-performance engines. The unconventional choice of material highlights the continuous innovation in rocket engine technology.

Witnessing the test firing of this advanced rocket engine is a thrilling experience, underscoring the remarkable progress in aerospace engineering. The video capturing the engine in action is a testament to the cutting-edge technology driving the future of space exploration.

The rapid development of this AI-generated rocket engine signifies a significant leap forward in the efficiency and speed of aerospace engineering. By leveraging artificial intelligence, companies like Leap 71 are revolutionizing traditional design processes and pushing the boundaries of technological advancement in the space industry.