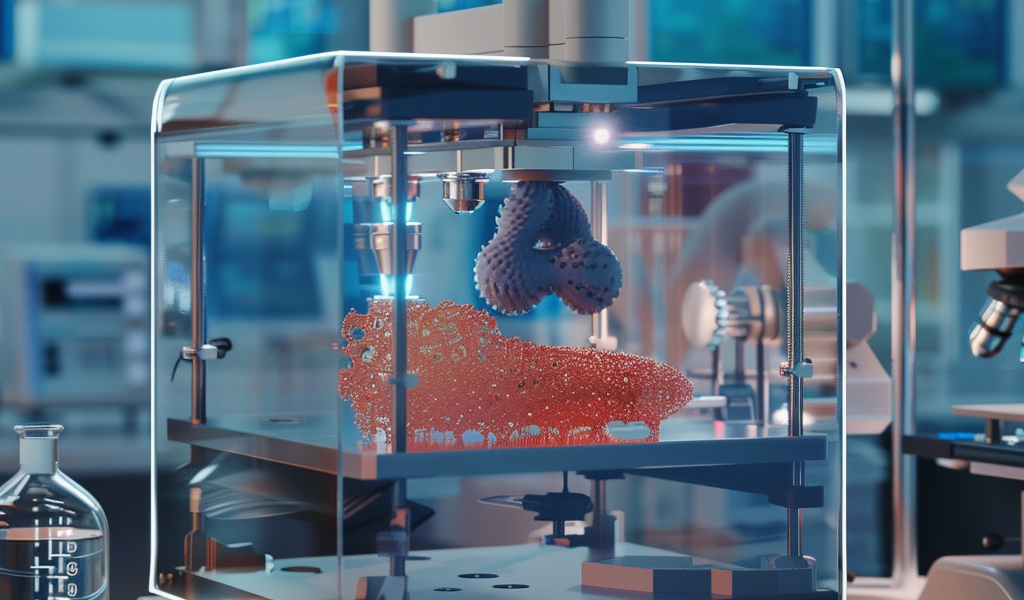

Researchers at Penn State University have unveiled a revolutionary advancement in the field of bioprinting with their innovative High-throughput Integrated Tissue Fabrication System for Bioprinting (HITS-Bio). This cutting-edge technology is capable of producing functional biological tissues at an unprecedented speed, achieving rates that are ten times faster than existing methods while ensuring high cell viability.

The HITS-Bio system utilizes cell clusters known as spheroids to construct tissues that exhibit a density similar to that of natural human tissues. Traditional bioprinting techniques often suffer from limitations such as cell damage and slow processing speeds. However, HITS-Bio overcomes these challenges by employing a digitally controlled nozzle array that allows for precise three-dimensional movements. This feature enables the simultaneous manipulation of spheroids, facilitating the rapid assembly of complex tissue structures with customizable patterns.

In practical tests, the research team successfully created a one-cubic-centimeter piece of cartilage tissue using 600 spheroids in under 40 minutes. This remarkable achievement not only surpasses the speed of traditional techniques but also maintains over 90% cell viability, a crucial factor for the functionality of the printed tissues.

The potential clinical applications of HITS-Bio were further demonstrated when the researchers utilized the technique to repair bone tissue in a rat model. During surgical procedures, spheroids that were programmed with microRNA were directly printed into a skull wound. This innovative approach significantly accelerated the healing process, with the wound showing a remarkable 91% healing rate after three weeks and reaching 96% after six weeks.

The introduction of HITS-Bio marks a significant milestone in the quest to develop lab-grown tissues and organs for medical applications. Future research is aimed at enhancing this technology by integrating blood vessels into bio-printed tissues. This advancement could pave the way for groundbreaking applications in organ transplantation and sophisticated disease modeling.

As regenerative medicine continues to evolve, the implications of HITS-Bio are profound. The ability to fabricate tissues and organs more rapidly and effectively could transform the landscape of medical treatments, offering new hope for patients requiring transplants or advanced therapeutic interventions.

In summary, the development of the HITS-Bio bioprinting system represents a pivotal advancement in tissue engineering, promising to accelerate the production of functional biological materials and revolutionize the field of regenerative medicine.