In a groundbreaking study published in Energy & Environmental Science, researchers from the Korea Institute of Science and Technology (KIST) have unveiled a novel silver-silica composite catalyst designed to enhance the efficiency of chemical reactions, particularly in the context of carbon dioxide (CO₂) reduction. The research, spearheaded by Dr. Hyung-Suk Oh and Dr. Woong Hee Lee from the Clean Energy Research Center, focuses on a unique approach to controlling local pH levels through a silica-hydroxide cycle.

The study highlights the intricacies of the CO₂ reduction process, illustrating how the generation of hydroxide ions (OH⁻) at varying current densities impacts performance. At elevated current densities, an abundance of hydroxide ions can inhibit the transfer of CO₂ to the catalyst surface, ultimately diminishing the catalyst’s efficacy. The researchers employed diagrams to depict these reactions, providing clarity on the mechanisms at play.

The foundation of this research is rooted in the carbonate-silicate cycle, a natural process that governs Earth’s inorganic carbon dynamics. This cycle involves the release of CO₂ into the atmosphere through volcanic activity after carbon is extracted from the air and sequestered in weathered minerals. The weathering of silicate rocks generates dissolved silica (SiO₂), which is crucial for the formation of carbonate rocks. These rocks are subsequently recycled back into silicate rock via volcanic processes, playing a significant role in regulating the planet’s temperature.

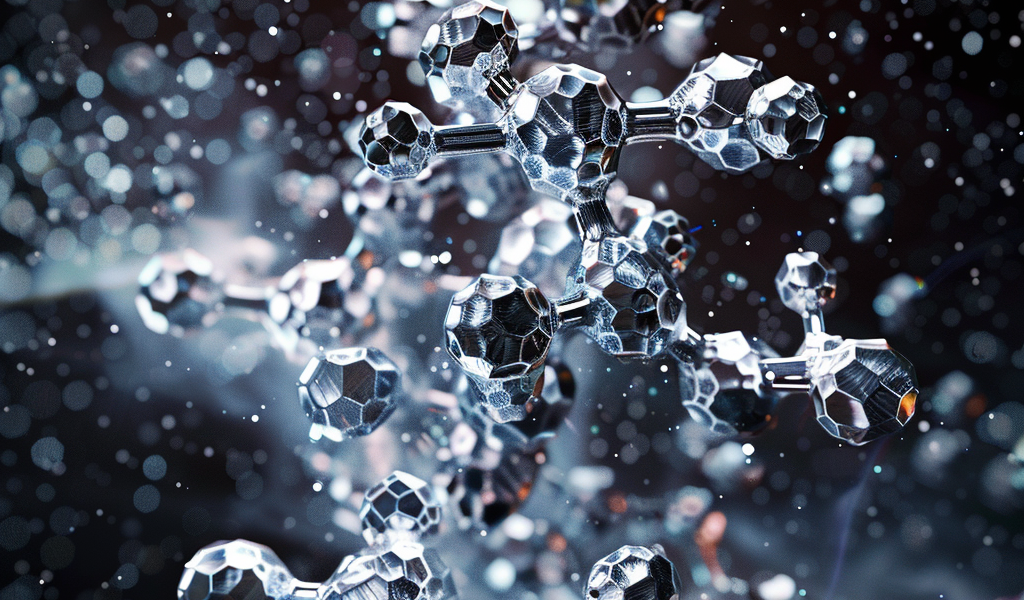

Silica has emerged as a vital component in electrochemical CO₂ conversion techniques. Silver catalysts have proven to be highly effective in the realm of Carbon Capture and Utilization (CCU) technology, particularly in transforming CO₂ into carbon monoxide (CO), a key raw material for the petrochemical industry. However, the commercial viability of silver catalysts has been hindered by issues such as particle agglomeration at high current densities, which leads to a significant decline in selectivity for CO production.

To tackle this challenge, the KIST research team developed an innovative silver-silica composite catalyst. This catalyst maintains the performance of silver while effectively regulating pH levels through the interaction of hydroxide ions with silica. The process involves the dissolution of silica into a silicate form, which then precipitates under neutral conditions, thereby mitigating performance degradation at higher current densities without compromising the catalyst’s physical structure.

In a remarkable achievement, the silver-silica composite catalyst demonstrated nearly 100% selectivity even at elevated current densities of 1 A cm⁻², contrasting sharply with traditional silver catalysts that lose selectivity at around 60% when operating at 800 mA cm⁻². This significant advancement positions the silver-silica composite catalyst as a promising solution for enhancing the efficiency of CO₂ reduction processes.

The implications of this research extend beyond laboratory findings, as the innovative catalyst could pave the way for more effective carbon capture technologies. As the world grapples with climate change and the urgent need to reduce greenhouse gas emissions, advancements such as these are crucial in the pursuit of sustainable energy solutions.

As the study progresses, the team at KIST is optimistic about the potential applications of their silver-silica composite catalyst in real-world scenarios. The ability to maintain selectivity and performance at higher current densities could revolutionize the field of CO₂ utilization, making it more commercially viable and efficient.

In summary, the development of the silver-silica composite catalyst represents a significant leap forward in the quest for effective carbon capture and utilization technologies. The innovative approach to pH regulation and the impressive selectivity at high current densities are promising indicators of the catalyst’s potential impact on the energy sector and the broader fight against climate change.