Groundbreaking 3D Printed Pills with Timed Drug Release Developed by University of Nottingham Researchers

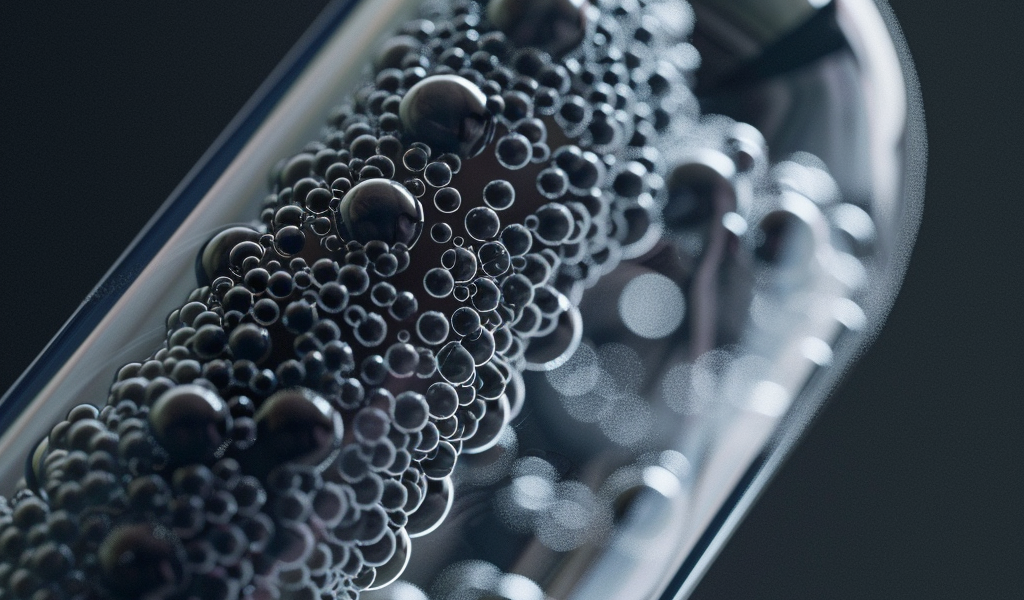

3D printed pills using a groundbreaking new technique have been developed, allowing for the creation of personalized medication with timed drug release capabilities. Researchers from the University of Nottingham’s Centre for Additive Manufacturing and School of Pharmacy have pioneered the use of Multi-Material InkJet 3D Printing (MM-IJ3DP) to fabricate custom pharmaceutical tablets.

The innovative method involves a unique ink formulation sensitive to ultraviolet light, which forms a water-soluble structure when printed. This structure controls the drug release rate within the tablet, enabling precise timing of dosage release. The tablets can incorporate multiple drugs, simplifying complex medication regimens into a single dose.

Dr. Yinfeng He, Assistant Professor in the Faculty of Engineering, highlighted the potential of this technology in revolutionizing drug delivery and advancing personalized medicine. However, challenges remain, such as the need for additional formulations to support a wider range of materials.

Professor Ricky Wildman emphasized the importance of refining these aspects to enhance the feasibility of MM-IJ3DP for broader application. The scalability of the technology is evident, with the ability to print 56 pills in a single batch, showcasing its potential for mass production of personalized medicines.

This advancement is particularly significant for diseases requiring precise timing and dosage accuracy in medication. The tailored drug release profiles offered by these 3D printed pills open up new possibilities for treating various conditions effectively.