Breakthrough in Tissue Engineering: Artificial Cartilage Developed Using 3D Printing Technique

A new breakthrough in tissue engineering has been achieved at TU Wien (Vienna) with the development of artificial cartilage using a unique 3D printing technique. This innovative approach, detailed in a study published in Acta Biomaterialia, could potentially revolutionize the field of regenerative medicine.

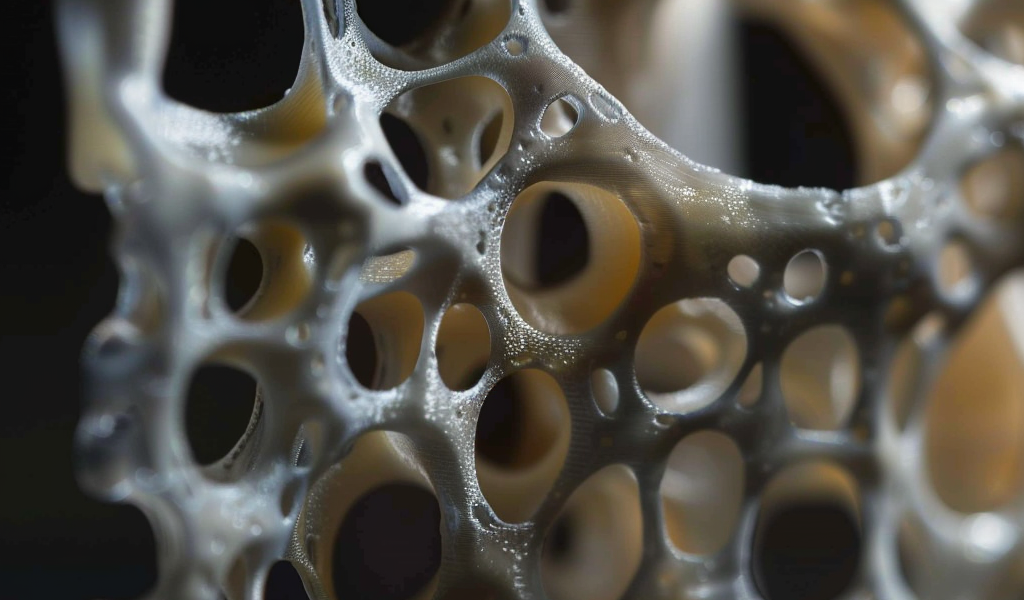

The process involves the creation of porous spheres from biocompatible and degradable plastic using a high-resolution 3D printing method. These spheres are then populated with cells and can be arranged into various shapes, allowing for the seamless formation of uniform, living tissue. The successful demonstration of this concept with cartilage tissue marks a significant advancement in tissue engineering.

According to Oliver Kopinski-Grünwald from the Institute of Materials Science and Technology at TU Wien, the main challenge in tissue cultivation lies in controlling the shape of the resulting tissue. To address this, the research team utilized laser-based 3D printing to produce miniature cage-like structures that provide a support system for the cells. These structures, resembling mini footballs, enable the creation of compact building blocks that can be assembled into desired shapes.

By introducing stem cells into these football-shaped mini-cages, the researchers were able to achieve even cell distribution and high cell density within the tissue elements. This level of precision was previously unattainable with conventional approaches, as highlighted by Prof. Aleksandr Ovsianikov, head of the 3D Printing and Biofabrication research group at TU Wien.

The study utilized differentiated stem cells, specifically tailored for cartilage tissue formation, to populate the mini-cages. This approach resulted in the seamless growth of uniform cartilage tissue, overcoming previous limitations associated with stem cell clumps changing shape and shrinking over time.

The innovative technique developed at TU Wien holds great promise for the future of tissue engineering and regenerative medicine. By providing a method to precisely control tissue formation, this advancement could lead to significant improvements in the development of artificial cartilage and potentially other types of replacement tissue, offering new hope for individuals with tissue injuries and degenerative conditions.