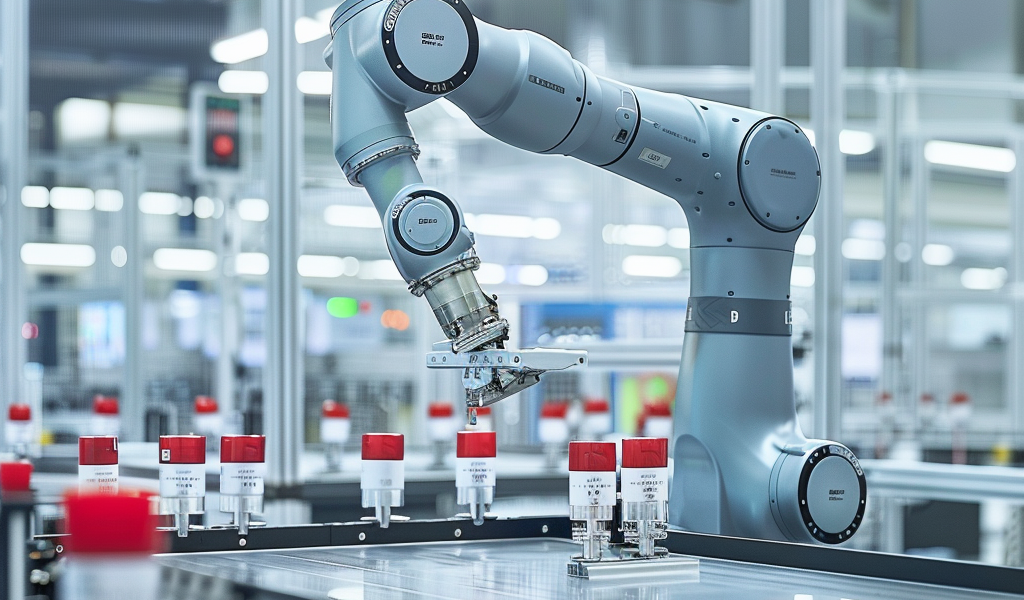

ABB Robotics has unveiled a groundbreaking feature for its GoFa collaborative robot (cobot) family, named Ultra Accuracy. This innovative addition significantly enhances the path accuracy of GoFa cobots to an impressive 0.03 mm, making it a game-changer for various industries that rely on precision production.

Andrea Cassoni, the Global Head of Collaborative Robots at ABB Robotics, emphasized the transformative potential of this feature. He stated, “By combining ultra-accurate path performance with GoFa’s inherent simplicity, safety, and flexibility, ABB’s new Ultra Accuracy feature opens a wide range of possibilities for the use of cobots in businesses including electronics, automotive, aerospace, and metal fabrication.” This statement underscores the versatility of GoFa cobots in meeting the demands of modern manufacturing.

The Ultra Accuracy feature is designed to cater to applications where exact positioning is essential to maintain product quality and ensure operational efficiency. Key applications include:

- Consumer Electronics Production: Tasks such as gluing and sealing require meticulous precision, which the Ultra Accuracy feature provides.

- Automotive Manufacturing: Laser welding of car parts benefits from the enhanced path accuracy, ensuring that components fit together seamlessly.

- Aerospace Manufacturing: The ability to layer composite materials with precision is crucial in aerospace applications, and the new feature supports this need effectively.

- Metal Fabrication: Precision laser cutting processes are optimized, allowing for intricate designs and high-quality outputs.

- 3D Printing: Accurate positioning of additive layers is essential for creating prototypes, and the Ultra Accuracy feature streamlines this process.

- Metrology Applications: Performing precision quality checks becomes more efficient and reliable with the enhanced accuracy.

One of the standout advantages of the GoFa cobots, particularly with the Ultra Accuracy feature, is their ability to combine precision with speed and a full range of motion. Unlike traditional 2D gantry systems often employed in electronics manufacturing, GoFa cobots provide full 6D motion capabilities right out of the box. This eliminates the need for additional calibration work, thereby enhancing flexibility and mobility across a broader range of tasks.

The compact and portable design of GoFa cobots allows for seamless integration into existing production lines. This integration occurs without the need for costly customizations, offering a significant edge over traditional gantry-based systems. Furthermore, the Ultra Accuracy feature can be deployed with minimal installation time, as calibration is conducted at the factory before delivery.

Another notable aspect of the Ultra Accuracy feature is its compatibility with ABB’s RobotStudio software. This combination allows for offline programming of applications, achieving a remarkable 99% match between simulation and real-world performance. This capability eliminates the need for touch-ups post-installation, ensuring that the implementation process is both precise and efficient.

ABB Robotics has made the Ultra Accuracy feature available for both new GoFa cobots and as a retrofit option for existing units. This flexibility means that businesses can upgrade their current systems to benefit from enhanced precision without needing to invest in entirely new equipment.

As industries continue to evolve with the advent of Industry 4.0, the demand for advanced automation solutions is on the rise. The introduction of the Ultra Accuracy feature for GoFa cobots positions ABB Robotics as a leader in providing innovative solutions that meet the challenges of modern manufacturing.

In conclusion, the Ultra Accuracy feature for GoFa cobots represents a significant advancement in the field of robotics and automation. By enhancing precision, speed, and ease of integration, ABB Robotics is paving the way for more efficient and effective manufacturing processes across various industries.